Solutions for Conveyors

Carlo Gavazzi is a market leader in Sensor, Switches, and Controls with one of the broadest range of products in the industry. With 90 years of automation experience, Carlo Gavazzi knows what it takes to manufacture products for tough environments and challenging applications. With local sales and distribution in over 100 countries, Carlo Gavazzi can support you locally around the world.

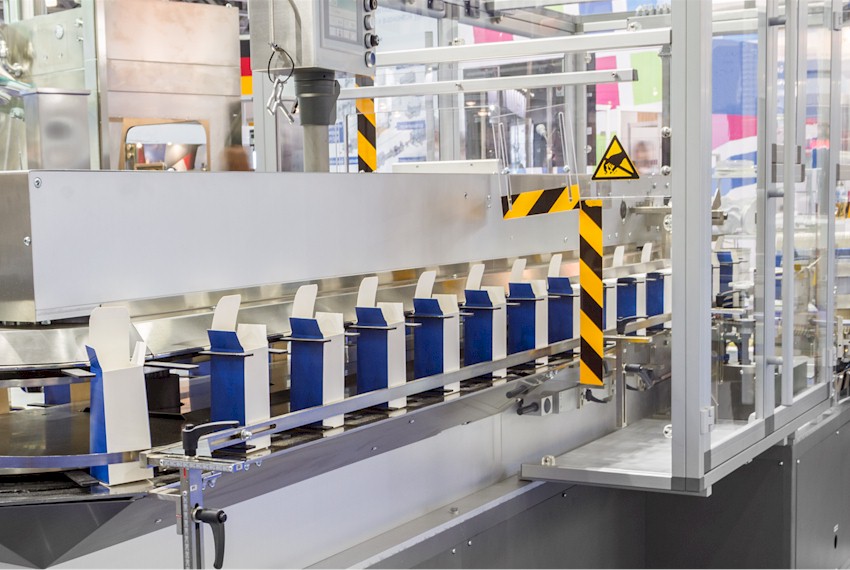

Conveyors are used in industries such as Food and Beverage, Pharmaceuticals, Packaging, Material Handling and Mining to name just a few. Carlo Gavazzi offers a broad range of products for use in product sensing, level control and monitoring, soft starting of motors, conveyor speed and jam detection, and gate and door monitoring.

Applications

CARLO GAVAZZI offers a wide range of sensors and controls for conveyors in food and beverage applications. We offer laser and Photoelectric Sensors for presence detection of product on the conveyor; Capacitive Sensors for presence detection and level detection, Ultrasonic Sensors for level detection, and Inductive Sensors for monitoring gates and conveyor speed. Many of our sensors are rated IP69K to withstand the demanding requirements for protection against water ingress into the sensor.

We also offer a broad range of controls and Monitoring Devices for monitoring motor overload, Safety Modules for connection to E-Stop and Magnetic Door Switches to ensure the machinery is shut down if guards or doors are not in place. In addition we offer Motor Soft Starters to reduce inrush current; limit stress to drive links, belts and chains; and to slowly start the conveyor to prevent jarring and over turning of bottles and containers.

CARLO GAVAZZI products are used extensively on conveyor based pharmaceutical applications. Photoelectric Sensors are used to detect proper cap placement on pill bottles and presence of individual pills in blister packs, Capacitive Sensors for presence and level detection, Ultrasonic Sensors for level detection, Inductive Sensors for gate monitoring and monitoring conveyor speed and Magnetic Sensors and Safety Modules for monitoring guards that protect against contact with moving parts.

Our comprehensive range of controls and Monitoring Devices are used for monitoring motor overload, earth leakage and out of range voltages. Our Motor Soft Starters are effective to prevent jarring and over turning of bottles and containers and reduce stress on the conveyor drive belts and linkages.

CARLO GAVAZZI products are used extensively in packaging applications. Photoelectric Sensors are used to detect the presence of containers and if box tops are closed, monitoring when labels and box supplies are running low; Capacitive Sensors for presence and level detection - including non-invasive montioring of level through the container wall; Ultrasonic Sensors for level detection; Inductive Sensors for gate monitoring and monitoring conveyor speed; and Magnetic Sensors and Safety Modules for monitoring guards that protect against contact with moving parts.

Our comprehensive range of controls and Monitoring Devices are used for monitoring motor overload, earth leakage and out of range voltages. Our Motor Soft Starters are effective to prevent jarring and over turning of bottles and containers and reduce stress on the conveyor drive belts and linkages.

Long conveyors used in mining applications are many miles long and there is the challenge of not only making sure that the conveyor shuts down when a pull cord is pulled but identifying which pull cord switch was pulled. Dupline Safe satisfies both of these requirements - an SIL 3 rated system for stopping the conveyor and addressable transmitters to indicate which pull cord switch is pulled.

At the heart of the system is the channel generator. It controls the communication in the system and connects to the field transmitters via a twisted pair communication cable (18-14 AWG) up to 3.1 miles long. Also connected to the communication cable is the Safety Receiver which is configured to drop out when a pull-cord transmitter is triggered by the pull-cord switch, thereby shutting off the conveyor. In addition, the status of the pull cord transmitters can be read by your PLC controller using one of our gateways (Profibus, Profinet, Modbus).

Close

Close