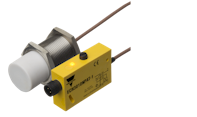

Capacitive Proximity Sensors

Carlo Gavazzi is a market leader in capacitive proximity sensor technology with one of the broadest and advanced portfolios in the industry. With over 35 years of experience, Carlo Gavazzi knows what it takes to manufacture sensors that are designed to withstand the rigors of your toughest applications. With local sales support centers located in 22 countries and independent distribution in over 100 countries, Carlo Gavazzi product and technical support is available around the world.

What is a Capacitive Sensor?

Capacitive proximity sensors detect nearly all materials – both metal and non-metal objects – and can even sense through wood or plastic. This is due to the technology being activated by the dielectric constant of a material. If the target material’s dielectric constant is significantly higher than another materials, often wood or plastic, a capacitive sensor can ignore the lower dielectric material and still detect the target material. This unique functionality allows capacitive sensors to detect fill levels of liquids, pellets, and powders through container walls.

Dielectric Constant Chart - Capacitive Sensors can detect anything greater than 1.2| Material | Dielectric Constant |

Material | Dielectric Constant |

Material | Dielectric Constant |

Material | Dielectric Constant |

|||

|---|---|---|---|---|---|---|---|---|---|---|

| ABS Pellets | 1.5 - 2.5 | Com, refuse | 2.3 - 2.6 | Oil, Turpentine | 2.2 | Rice | 3 - 8 | |||

| Acetone | 19.5 - 20 | Epoxy resin | 2.5 - 6 | Oil, vegtable | 2.5 - 3.5 | Rubber, hard | 4 | |||

| Acrylic resin | 2.7 - 6 | Ethyl alcohol | 24 | PE Pellets | 1.5 | Rubber, raw | 3 - 5 | |||

| Air, vacuum | 1 | Flour | 2.5 - 3 | Perspex | 3.2 | Sand | 3 - 5 | |||

| Alcohol, industrial | 16 - 31 | Fly ash | 1.5 - 1.7 | Petroleum | 2.2 | Silicon | 2.8 | |||

| Aluminum powder | 1.6 - 1.8 | Glass | 5 | Polyamide | 5 | Soap powder | 1.2 - 1.5 | |||

| Aluminum sulphate | 6 | Grain | 3 - 8 | Polyethylene | 2.3 | Sodium sulfite | 5 | |||

| Araldit | 3.6 | Hexane, liquid | 5.8 - 6.3 | Polypropylene | 2.3 | Soft rubber | 2.5 | |||

| Asphalt | 2.5 - 3.2 | Hydrochloric acid | 4 - 12 | Polystyrene | 3 | Starch | 2 - 5 | |||

| Bakelite | 3.6 | Iron oxide | 14.2 | Polyvinyl chloride | 2.9 | Sugar | 3 | |||

| Calcium carbonate | 1.8 - 2.0 | Kerosene | 2.8 | Porcelain | 4.4 | Sugar, granulated | 3 | |||

| Calcium oxide | 11.8 | Marble | 8 | Potassium chloride | 4.6 | Sulfuric acid | 84 | |||

| Calcium sulphate | 5.6 | Mica | 6 | PP pellets | 1.5 - 1.8 | Teflon | 2 | |||

| Carbon dioxide | 1.6 | Nitrogen, liquid | 1.4 | Presipan | 4 | Toluene, liquid | 2.0 - 2.4 | |||

| Celluloid | 3 | Nylon | 4 - 5 | Paraffin | 2.2 | Urethane | 6.5 - 7.1 | |||

| Cement | 1.5 - 2.1 | OIl, heavy | 2.6 - 3.0 | PVC powder | 1.4 | Water | 48 - 80 | |||

| Coffee, powder | 2.4 - 2.6 | Oil, mineral | 2.1 | Quartz glass | 3.7 | Water, chlorine | 2 | |||

| Coke | 1.1 - 2.2 | Oil, transformer | 2.2 | Quartz sand | 4.5 | Wheat powder | 2.5 - 3 |

How to Properly Select a Capacitive Proximity Sensor

There are many factors to consider when selecting the best capacitive proximity sensor for your application. These considerations can be broken down into five categories, which can be found on this TOP TIPS resource paper we did in conjunction with Plastics, Machinery and Manufacturing (PMM) and Machine Design. View

Our Capacitive Proximity Sensor Range

Applications for Capacitive Proximity Sensors

Rather than focusing only on producing high-quality parts, which is still a priority, many injection and extrusion manufacturers are looking to streamline their processes and reduce scrap with the concept of ‘smart’ machines.

At Carlo Gavazzi we can help injection molding equipment manufacturers facilitate the transition to ‘smart machines’ through our NRG digital solid state relays for precise temperature control and IO-Link capacitive sensors for monitoring levels of plastic pellets in machine material delivery systems.

Agriculture Feeding Systems – feeding distribution systems are critical to the quality and safety of livestock farming; automation contributes to a better animal welfare and higher production. The food distribution can be controlled by capacitive sensors, often combined with a solid state relay and soft starter.

Agriculture Harvesting Machinery – agricultural machinery needs reliable and durable parts and components capable of working long hours in difficult external conditions, exposed to harsh environmental operating conditions. Capacitive sensors can detect the presence of grain, plants, or product to signal a fill level.

Agriculture Seed Silos – Capacitive sensors are an efficient means for level measurement in silos, dryers, and storage containers.

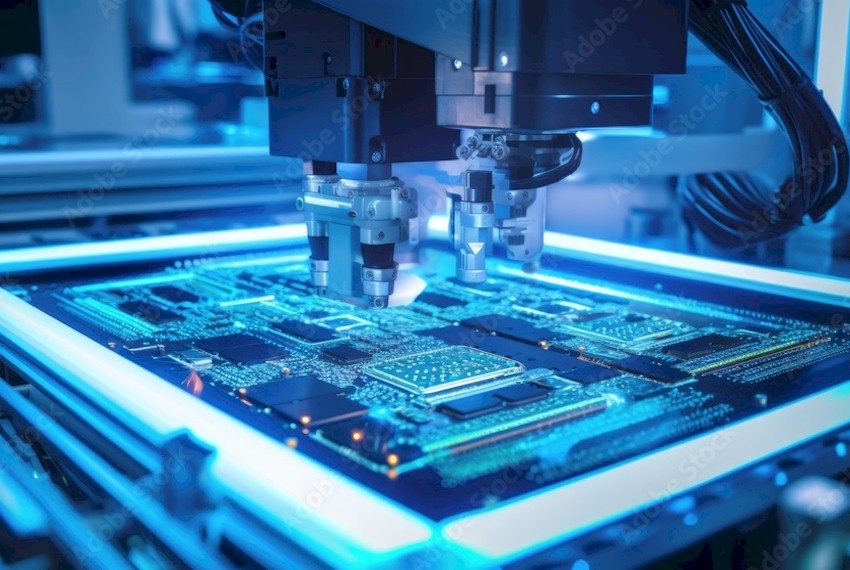

Increasing demand for integrated automation in the production, distribution and storage of electronics, wafers and PCB’s, require accurate monitoring of positions for collision-free transportation.

Fast and accurate detection and even product counting are among the critical functions capacitive sensors offer to drive process efficiency and productivity. Thanks to the embedded functions using capacitive sensors with IO-Link, a high degree of control and diagnostics are possible.

Food and Beverage Packaging – Accurate detection and integrated automation functions in complex and flexible food and beverage packaging conveying systems are crucial to reach maximum productivity, to reduce downtime and enable predictive maintenance.

Carlo Gavazzi capacitive sensors are used to detect presence of product with any color or transparency, fill level in bottles / containers, verify presence of caps on bottles, and more. Additionally, field devices (including capacitive sensors) can be connected using IO-Link for the highest level of automation control and integration.

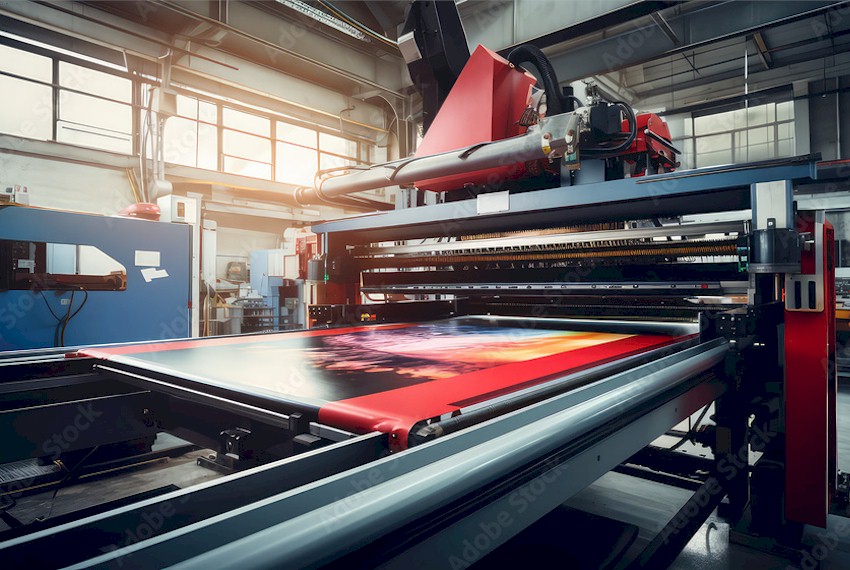

Digital printing processes are widely used in conveying handling systems for packaging lines, tile and ceramic production. Capacitive sensors can detect the presence of product to ensure positioning for handling and printing as well.

Additionally, ink levels can be detected by a capacitive sensor to increase quality and reduce downtime of the printing process.

Close

Close